What is Aquaflex?

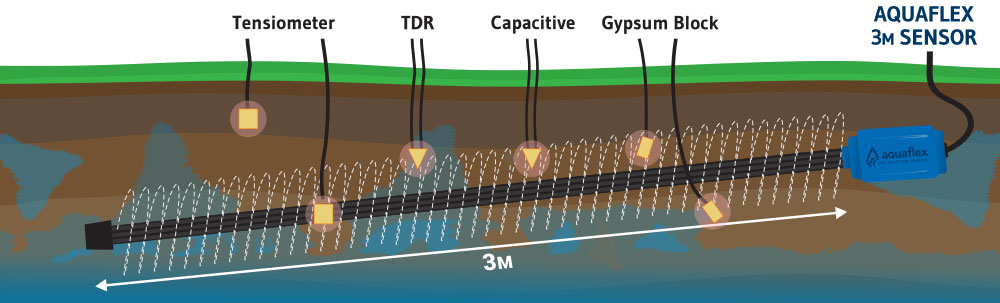

Aquaflex is a novel solution for capturing the soil moisture for use in Agriculture. Multiple can be used to provide additional information about how deep the water is. Unlike the majority of sensors on the market which are cylindrical and installed into a deep round hole, the Aquaflex is installed into a trench.

The advantages of the Aquaflex are that there is more soil measured and therefore you are more likely to get a realistic representation in your recorded data.

Manufacturing Excellence

When tasked with manufacturing the Aquaflex, I was given an outdated procedure, and a blank slate for how I set up the work space. Whilst I was given a manufacturing document, it detailed the steps, but now how best to perform them.

PCB testing using sound

The Aquaflex test jig is an old piece of software and hardware. It uses a 12 position dial with each dial performing another test. Some tests were seconds long, whilst some were up to 30 seconds long. Using Python I created a simple beeper script that would await the pop up messages that the test software generated, by using short and long beeps to indicate different testing stages I could perform tests without looking. This method required less attention to the pop ups that showed on the screen, and reduced fatigue when PCB testing, and increasing speed.

Cutting 10 meter cables made quick.

The 10 meter cable is a digital signal cable to connect the sensor PCB to the datalogger. Drums came in 100M lengths and length didn’t have to be exact. By reframing the problem as trying to get 10 equal lengths from the data cable I could significantly reduce the amount of physical labor required, and time required. I did this by 3D printing a span of 10 U shaped groves that could be glued to the original cable drum. By wrapping the cable around the cable drum, and using the grooves to count the wraps I could simply spin the drum to a certain point, cut, release tension, and zip tie. Another advantage is that by wrapping the cable around a drum the cable was already coiled up which is the state it needed to be in for final packaging.

3D printed solutions

I leveraged my ability to create 3d models heavily in the manufacture process.

• Slots and guides for the cutting of the sensor cable. This had to be as exact as possible and the slots and guides ensured the cable was as straight as possible.

• Potting jig, the potting jig had to be reconstructed but I was able to create an O shaped slot for potting cups to sit into and a router cut guide. I could use a router to rough cut the holes needed, and then glue in place the slots to perfectly seat the potting cups.

• The Aquaflex has software to measure the sensor in certain states and from this information it can create a trimming profile. I found that the orientation of the sensor in the water bath could dramatically effect the sensor readings. By creating a U shaped slot that would sit in the water bath, I was able to fix the sensor block in place for all sensors and create more accurate readings for the trimming process.

Recording results, reducing recalls

I improved the process of the final quality assurance step. By recording the sensor in a variety of states I was able to enter this into a google spreadsheet which allowed us to track the average performance of each individual sensor, it’s serial number, as well as identify outliers. This information is key as it acts as another resource when trying to diagnose data issues as this spreadsheet can referenced against a customers serial number. It also allowed for the creation of metrics to evaluate batch results between batches.